Post Protector vs Perma-Columns for my pole barn?

Which is the better option to keep my post frame building posts from decay, Post Protectors or Perma-Columns?

In the past several decades posts frame buildings have undergone many changes and most of them for the better. One of which is several types of improved foundation systems. While it is still completely acceptable to simply put a wood post treated with Alkaline Copper Quaternary (ACQ) in the ground and shovel dirt around it and walk away like it was 1993, most folks, especially those planning a barn home, care a bit more about their investment, and want to see options to protect their foundation.

Also your bank may want to see a concrete foundation in order to finance it. Or perhaps your prospective buyer in the future may be nervous about wood posts in the ground. This article will deal with the two most popular alternatives to treated wood in the ground.

This is one of the most tried and true methods in foundations. Concrete has no tensile strength, Meaning it will not bend, hence its tendency to crack. However it is unmatched in its ability to withstand straight downward pressure. (compression strength)

A Perma-Column is a shaft of concrete rated at 10,000 psi (pounds per sq inch of compression.) So a 6×6 post doing simple math 6×6 = 36 x 10,000 would take 36,000 lbs of downward pressure before it would give out due to straight downward pressure. In addition they are built with fiberglass fibers and rebar encased in the concrete to reduce the possibility of buckling. Why so much overkill? Well, if you recall, concrete has no tensile strength. In order to keep this narrow shaft of concrete from buckling sideways they had to raise the psi on the concrete mix and install the necessary reinforcements. The end result is what we are interested in, and that is a completely maintenance free and fully concrete foundation that is as good or better than any concrete basement wall. (Basement walls are poured at around 4000-4,500 psi mix)

As you can see on their website, there are 1/4″ steel metal plates that are powder coated and through bolt into the sides of the wood post. These metal plates are connected to the internal rebar of the concrete shaft for maximum strength against shear force.

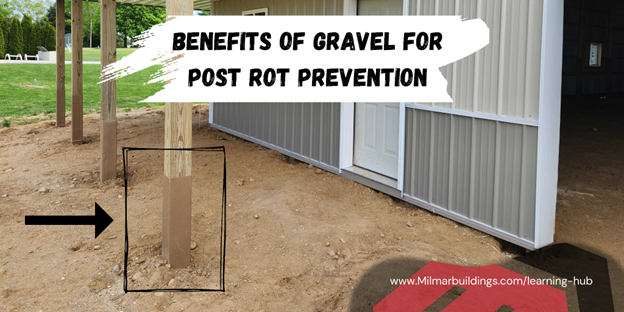

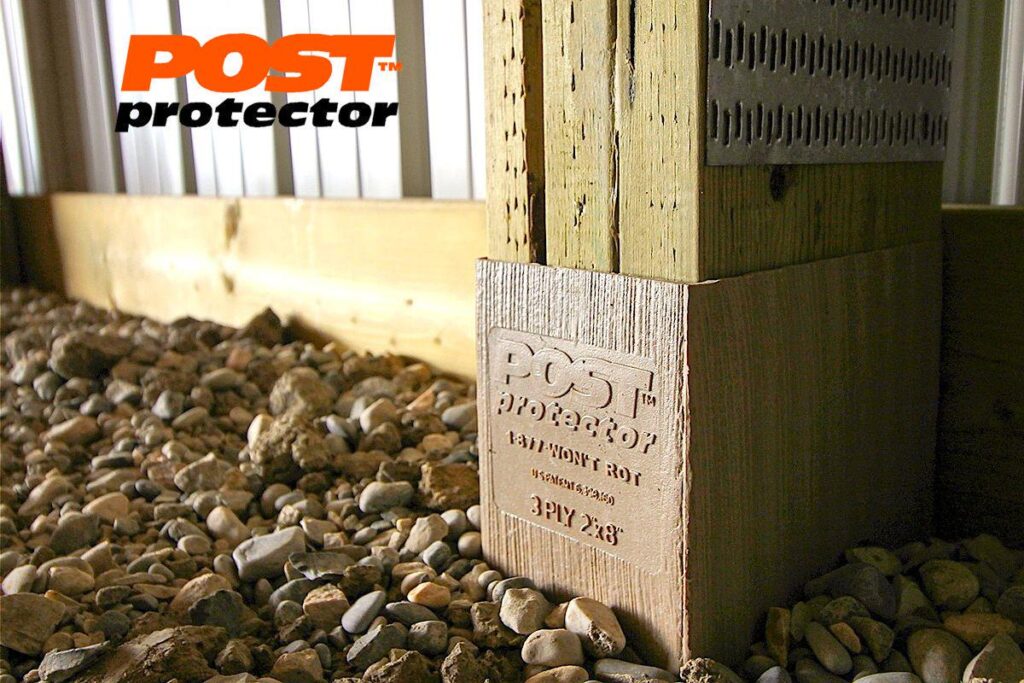

One of the more recent improvements to post frame foundations that Milmar has added to our options is Post Protector sleeves. Essentially, it is a HDPE post boot. They simply slide over the bottom of the posts and are lagged into the side of the wood post. There are optional weep holes at the base to drain out any water that may get into the sleeve. In addition there are raised ridges along the sides of the sleeve to prevent uplift. This is a good alternative for someone who is confident in the drainage of their particular site and wants a more cost effective and easier to install solution. Simply put, no soil contact, no rot! This is a good alternative for buyers who want protection without breaking the bank.

Post Protector also makes other products that fit well with the post sleeves such as HDPE grade board guard (another rot area although not structural). Our teams can install post protectors faster than they can Perma-Columns so that’s another cost savings.

Bottom line, concrete is always a no-risk bet. There is zero risk of concrete rotting. Concrete lasts for thousands of years. It’s one the oldest concepts in the history of building. However when there are cost constraints involved we like to have smart alternatives.

Either Perma-Columns or Post Protectors will make your building foundation last far longer than having nothing protecting the base of your posts, so make the smart choice of upgrading your building plans with one or the other!

Originally posted January 2023